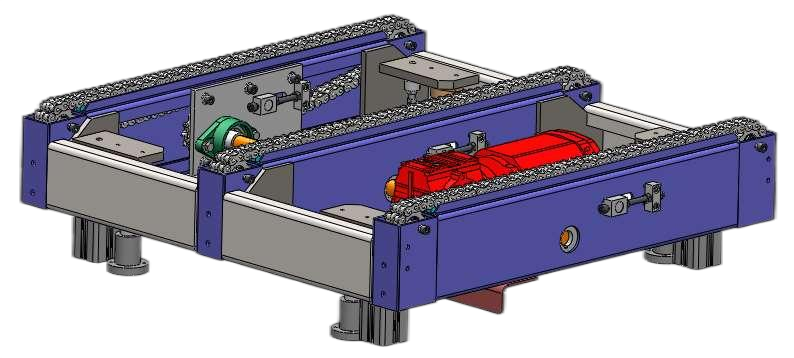

·The height of the stack can be adjusted to ensure a smooth transition;

·Forklift limit device protects the stacking position from forklift collision;

·The guardrail is adjustable, making it easy to adjust when changing between two stacking positions;

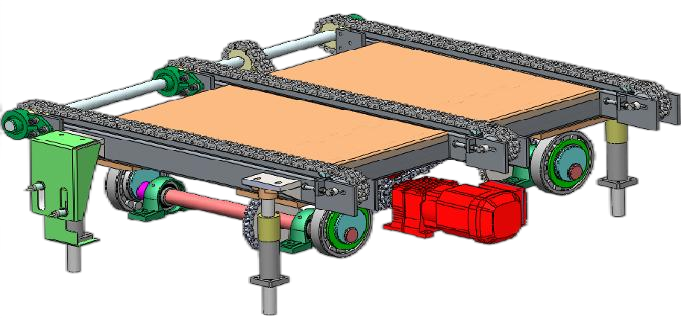

·Carbon steel spray coating structure, carbon steel spray coating side plate, carbon steel spray coating leg, 10B-2 chain;

·Carrying capacity: ≥ 1000kg;

·The noise level during operation is below 70 decibels;

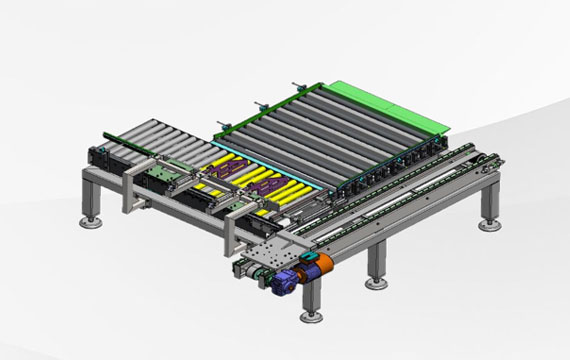

·Top lifting conveyor stack: used for tray right angle conveying;

·Carbon steel spray coated structural components, using a 3.2SEW power head assembly with a cylinder lifting mechanism;

·Carrying capacity: 1000kg;

·The noise level during operation is below 75 decibels.

There are 1600 and 2000 standard length pallets on the chain stacking line.

Double row roller chains are used for palletizing, ensuring smooth and non slip transportation, simple maintenance, and strong adaptability to conveying Sichuan style pallets.